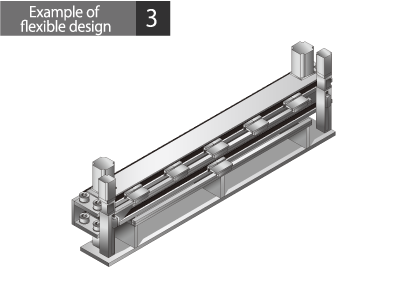

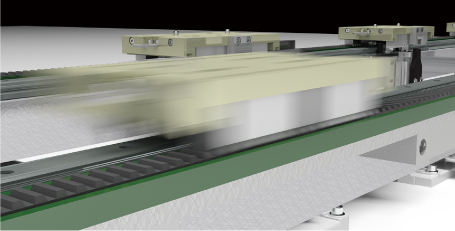

Through servo-motor

control, smooth acceleration

movement and slow stop are

possible. Moreover, the

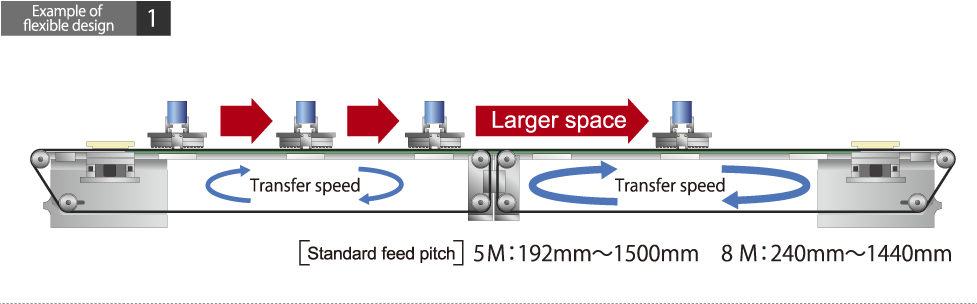

there is no contact between

pallets and smooth

conveyance is possible. Due

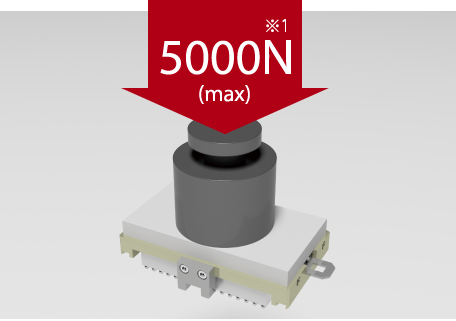

to high rigidity, it can convey

without vibration even if at

high-speed.

Servo-motors.

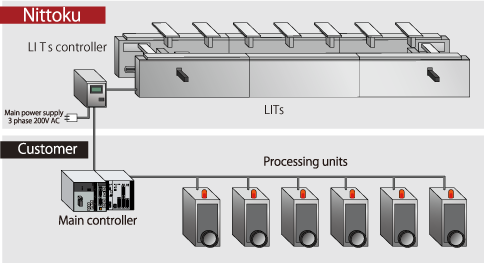

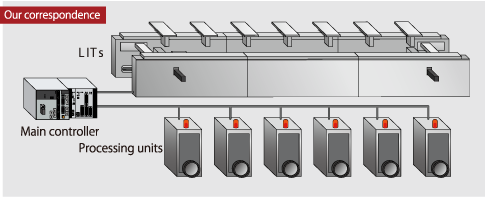

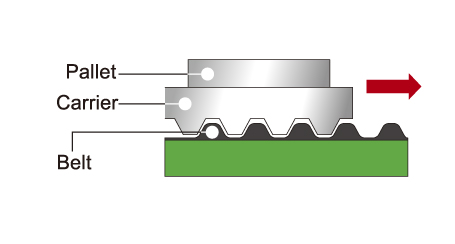

Conveys the carrier placed

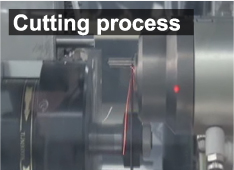

Download Windows Media Player

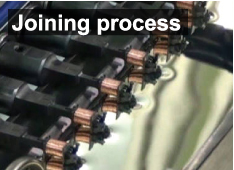

Download Windows Media Player